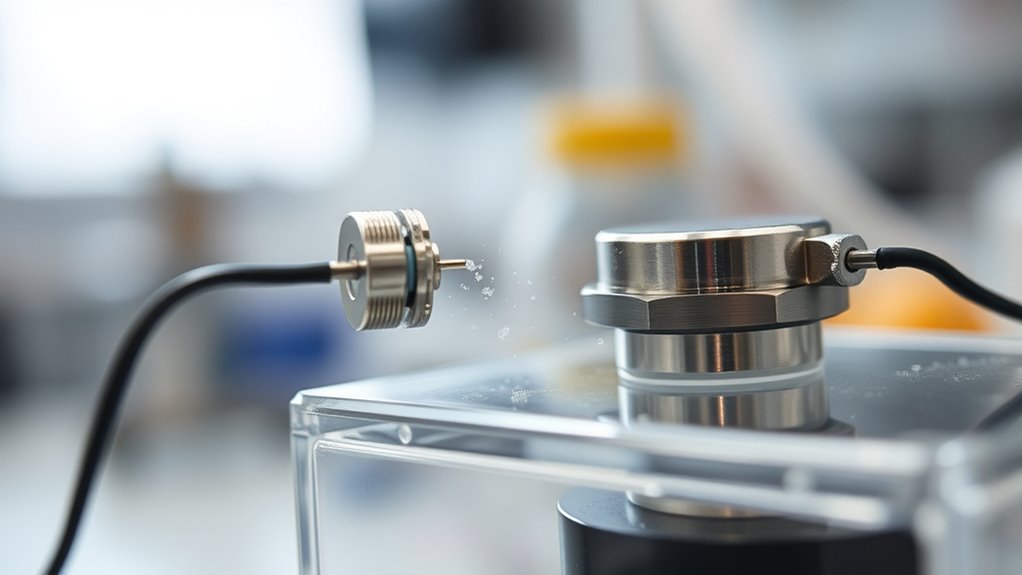

Piezo sensor technology detects dust in real time by producing an electric charge or voltage when dust particles impact the sensor surface, offering high sensitivity and immediate alerts. You benefit from its cost-effective, durable design suitable for harsh environments, making it popular in industries like manufacturing and power plants. While calibration and environmental factors can pose challenges, ongoing advancements aim to improve accuracy and reliability. Explore how these innovations can enhance your dust monitoring systems as you continue.

Key Takeaways

- Piezo sensors generate electric charge or voltage when impacted by dust particles, enabling real-time dust measurement.

- Regular calibration ensures accurate detection of small dust particles and maintains sensor reliability over time.

- Durable piezo sensors withstand harsh industrial environments, providing continuous dust monitoring with minimal maintenance.

- Environmental factors like humidity and vibrations can affect sensor accuracy, requiring shielding and proper installation.

- Advances include wireless data transmission and improved calibration techniques for more precise, real-time air quality monitoring.

Principles of Piezoelectric Sensing for Dust Detection

Piezoelectric sensing for dust detection relies on the ability of certain materials to generate an electric charge when subjected to mechanical stress. When dust particles impact or vibrate the sensor surface, the piezoelectric material produces a voltage proportional to the force. To guarantee accurate readings, regular piezo calibration is vital, helping you maintain sensor precision over time. Sensor durability plays a key role, as dust-laden environments can wear down components; selecting robust materials and protective coatings extends sensor lifespan. The inherent sensitivity of piezoelectric sensors allows for real-time detection of dust particles, making them ideal for continuous monitoring. Additionally, understanding the high contrast ratio of projectors is crucial for optimizing image quality in home cinema setups, especially in dimly lit environments. By understanding these principles, you can optimize sensor performance, guaranteeing reliable operation even in challenging industrial settings.

Advantages of Using Piezo Sensors in Dust Monitoring

One of the key advantages of piezo sensors in dust monitoring is their ability to provide real-time, high-sensitivity detection of airborne particles. This enables you to respond swiftly to dust level changes, ensuring safety and compliance. Additionally, piezo sensors are cost-effective because they require less maintenance and have lower operational costs compared to traditional methods. Their small size and adaptability give you installation flexibility, allowing you to deploy them in various environments without significant modifications. To illustrate:

| Advantage | Benefit | Application Scope |

|---|---|---|

| Cost efficiency | Lower maintenance and operational costs | Budget-friendly dust monitoring solutions |

| Installation flexibility | Easy to install in diverse settings | Use in confined or complex spaces |

| Real-time detection | Immediate dust level alerts | Preventing hazards and ensuring safety |

| Sensitivity | Detects minute dust particles | Accurate air quality assessment |

Furthermore, their robust construction ensures durability even in harsh environmental conditions.

Applications of Piezo Sensor Technology in Industry

Piezo sensor technology has found widespread applications across various industries due to its ability to deliver precise, real-time data. In dust monitoring, these sensors detect dust particles with high sensitivity, making them ideal for environments like manufacturing plants, cleanrooms, and power stations. You can rely on piezo sensors to provide immediate feedback on dust levels, helping you maintain safety standards and product quality. Proper sensor calibration is essential to guarantee accurate measurements, especially when detecting small dust particles. This calibration process fine-tunes the sensor’s response, reducing errors and improving reliability. Additionally, understanding the different types of headphone jacks can be crucial when integrating sensor systems with various audio-visual equipment. By integrating piezo sensors into your dust control systems, you benefit from continuous monitoring, quick response times, and improved environmental management across multiple industrial sectors.

Challenges and Limitations of Piezo Dust Sensors

Despite their advantages, piezo dust sensors face several challenges that can impact their effectiveness. Calibration issues are common, requiring frequent adjustments to ensure accurate readings, especially when sensor conditions change over time. Environmental interference also poses a significant problem; dust particles, humidity, temperature fluctuations, and electromagnetic noise can distort sensor signals. These factors may lead to false positives or inaccurate dust concentration measurements. Additionally, piezo sensors are sensitive to mechanical vibrations, which can cause false readings if not properly isolated. To get reliable data, you need to address these limitations through careful calibration, shielding, and environmental controls. Recognizing these challenges helps you optimize sensor deployment and maintain precise dust measurement in real-world conditions. Furthermore, ongoing research in AI in Education and automation technologies can provide innovative solutions to improve sensor accuracy and data analysis.

Future Developments in Piezo-Based Dust Measurement

Advancements in sensor technology are paving the way for more accurate and reliable dust measurement systems. Future developments focus on enhancing sensor calibration methods, allowing for precise readings even in complex environments. These improvements will reduce drift and ensure consistent performance over time. Additionally, increasing environmental durability is a key goal, enabling sensors to withstand dust, moisture, temperature fluctuations, and chemical exposure without losing sensitivity. Researchers are exploring new materials and protective coatings to extend sensor lifespan and maintain calibration accuracy. Integration with smart systems and wireless data transmission will make dust monitoring more real-time and accessible across various industries. Incorporating sensor calibration techniques will further improve measurement precision, ensuring more dependable dust measurement, supporting better air quality control and regulatory compliance.

Frequently Asked Questions

How Does Temperature Affect Piezo Sensor Accuracy in Dust Detection?

You might wonder how temperature impacts piezo sensor accuracy in dust detection. Temperature variations can affect sensor stability, causing readings to drift. To maintain accuracy, you should perform temperature calibration regularly, ensuring the sensor compensates for thermal changes. This calibration helps you keep the sensor stable across different conditions, reducing measurement errors and ensuring reliable, real-time dust detection even in fluctuating temperature environments.

What Maintenance Is Required for Piezo Dust Sensors Over Time?

Think of your piezo dust sensors as vigilant guardians that need regular tune-ups. You should perform calibration procedures periodically to guarantee accuracy and detect any drift. Keep an eye on their sensor lifespan by inspecting for wear and tear, cleaning off dust buildup, and replacing components when necessary. This routine maintenance sustains their precision and longevity, preventing them from becoming silent sentinels that miss critical dust measurements.

Can Piezo Sensors Differentiate Between Dust Particle Types?

You wonder if piezo sensors can differentiate between dust particle types. While they excel at detecting particle size and real-time dust levels, they typically can’t identify specific dust types directly. To improve accuracy, you need to regularly calibrate the sensor, considering particle size variations. This calibration helps guarantee reliable measurements, but distinguishing dust types usually requires additional analysis or complementary sensor technologies.

Are Piezo Sensors Suitable for Outdoor Dust Monitoring?

You might wonder if piezo sensors work well outdoors for dust monitoring. They can be suitable, but you need to consider corrosion resistance since outdoor environments expose sensors to moisture and chemicals. Regular calibration procedures are vital to maintain accuracy over time. With proper protection and maintenance, piezo sensors can effectively measure dust levels outdoors, providing reliable real-time data for environmental monitoring.

How Cost-Effective Are Piezo Sensors Compared to Other Dust Measurement Methods?

Imagine you’re choosing a dust monitoring method for your factory. Piezo sensors might seem pricey upfront, but their durability and real-time data can reduce long-term costs. Compared to traditional filters or optical methods, they often have a better cost comparison, especially when considering maintenance and accuracy. So, if budget considerations matter, piezo sensors could be a cost-effective option, helping you save money while ensuring precise dust measurements.

Conclusion

Just as Da Vinci envisioned precise tools to understand the unseen, piezo sensors empower you to detect dust in real time with accuracy. Their innovative approach *unleashes* new possibilities across industries, transforming dust monitoring from guesswork to certainty. While challenges remain, ongoing advancements promise a future where you can rely on these sensors like a trusted compass. Embrace this technology, and step confidently into a cleaner, safer, and more efficient tomorrow.