To fully understand vacuum terminology, you need to grasp key concepts like vacuum, pressure units (Torr, Pascal, inches of Hg), and the types of vacuum systems (dry, cryogenic). You’ll learn about essential equipment such as pumps, valves, and gauges, plus techniques like leak detection and baking. Knowing common terms helps with troubleshooting, maintenance, and system optimization. Continue exploring these terms to master vacuum technology and improve your system’s performance.

Key Takeaways

- Defines essential vacuum terms and measurement units like Torr, Pascal, and inches of Hg for clarity.

- Explains different vacuum system types, such as dry and cryogenic, and their applications.

- Covers key equipment components, including pumps, valves, and gauges, with their functions.

- Describes common processes like leak detection, baking, and pressure relief techniques.

- Provides troubleshooting tips and maintenance vocabulary to ensure system integrity and optimal performance.

Basic Vacuum Concepts and Definitions

Understanding the basics of vacuum technology begins with knowing what a vacuum is. Essentially, a vacuum is a space where air and other gases are reduced to very low pressure, creating a near-empty environment. This is achieved through vacuum sealings, which prevent gas from entering or escaping a sealed container. Pressure differentials play a key role here; they occur when the pressure inside a sealed space differs from the outside atmosphere, driving gas movement. Maintaining these differentials is vital for creating and sustaining a vacuum. Whether for industrial processes, scientific research, or packaging, understanding these core concepts helps you grasp how vacuums are generated and controlled. The process of air removal involves specialized pumps that lower the pressure further, enabling precise applications across various fields. This foundation sets the stage for exploring different types of vacuums and their specific applications.

Types of Vacuum and Their Characteristics

Vacuum types are classified based on the level of pressure achieved and the methods used to generate them. For example, dry vacuum systems use mechanical pumps without oil, making them clean and suitable for sensitive applications. They typically reach medium to high vacuum levels. Cryogenic vacuum, on the other hand, relies on extremely low temperatures to condense gases, producing ultra-high vacuum conditions. This type is ideal for applications requiring extremely low pressures, such as space simulation or particle physics. Both dry vacuum and cryogenic vacuum have distinct advantages: dry systems minimize contamination, while cryogenic systems achieve unparalleled vacuum levels. Understanding these characteristics helps you select the right vacuum type for your specific needs, ensuring optimal performance and efficiency in various industrial and scientific applications. As technology advances, automation in industries continues to enhance the efficiency of vacuum systems, enabling more precise and reliable operations.

Vacuum Measurement and Units

Measuring vacuum levels accurately is essential for ensuring your system performs as expected. Understanding vacuum measurement involves knowing the various vacuum units used to quantify pressure. Different units include Torr, Pascal, and inches of mercury, each suited for specific applications. To help clarify, here’s a comparison:

| Unit | Typical Range | Common Use |

|---|---|---|

| Torr | 760 to 10⁻³ Torr | Laboratory vacuum systems |

| Pascal (Pa) | 101,325 to 10⁻⁹ Pa | Scientific and industrial use |

| Inches Hg | 29.92 to 10⁻³ inches Hg | HVAC and leak testing |

| Millibar | 1,013 to 10⁻² mbar | Process control |

| Atmosphere | 1 atm = 101,325 Pa | Standard pressure reference |

Choosing the correct vacuum units helps you measure and compare vacuum levels accurately for your application. Proper understanding of vacuum measurement units ensures precise monitoring and system performance.

Vacuum Equipment and Components

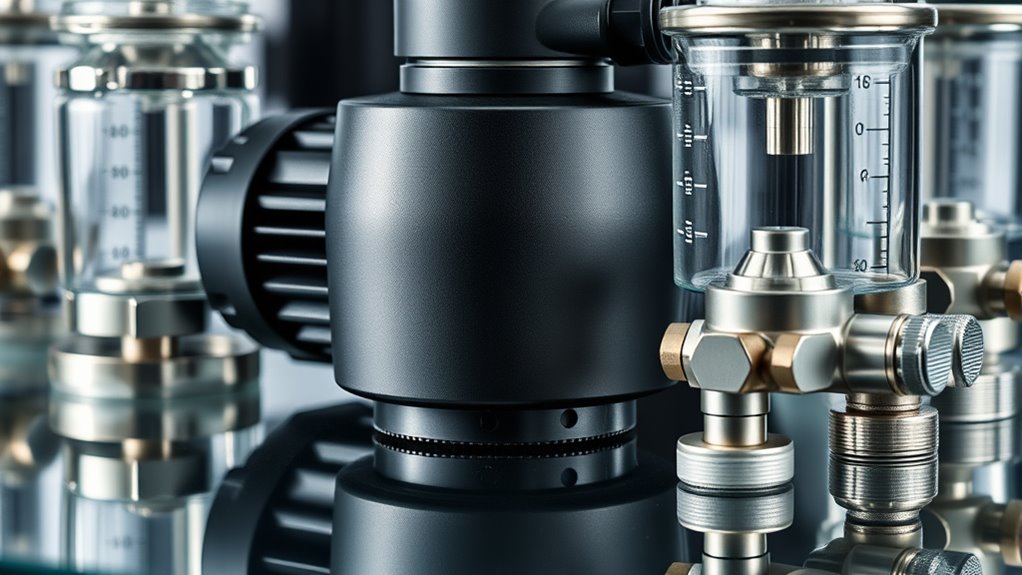

Understanding vacuum equipment starts with knowing the different pump types and how they work to create and maintain vacuum. Valves and gauges are essential for controlling and measuring pressure levels accurately. Together, these components form the core of any effective vacuum system. Additionally, selecting the appropriate vacuum pump is critical for achieving desired performance levels across various applications.

Pump Types and Functions

Choosing the right pump type is essential for achieving your desired vacuum level and maintaining efficient operation. Piston pumps use a reciprocating piston to compress or move air, suitable for high vacuum applications. Rotary vane pumps, on the other hand, feature a rotating vane inside a cavity to create a seal and reduce pressure, ideal for medium vacuum needs. Both pump types serve specific functions: piston pumps excel in providing high vacuum with precise control, while rotary vane pumps offer continuous, reliable operation for general use. Understanding these differences helps you select the best pump for your system, ensuring ideal performance and longevity. Proper pump selection minimizes downtime and enhances your overall vacuum process efficiency. Additionally, integrating automation can optimize pump operation and maintenance, leading to increased efficiency and reduced operational costs.

Valves and Gauges

Have you ever wondered how you control and monitor vacuum systems effectively? It all comes down to using the right equipment, like a vacuum valve and pressure gauge. A vacuum valve lets you open, close, or regulate airflow within the system, giving you precise control over pressure levels. Meanwhile, a pressure gauge provides real-time readings of the system’s pressure, so you know exactly when you’ve reached your desired vacuum level. Together, these components ensure your system runs smoothly and safely. The vacuum valve helps isolate sections for maintenance or adjustments, while the pressure gauge offers critical feedback for fine-tuning. Mastering their use is vital for maintaining ideal vacuum conditions and preventing system failures.

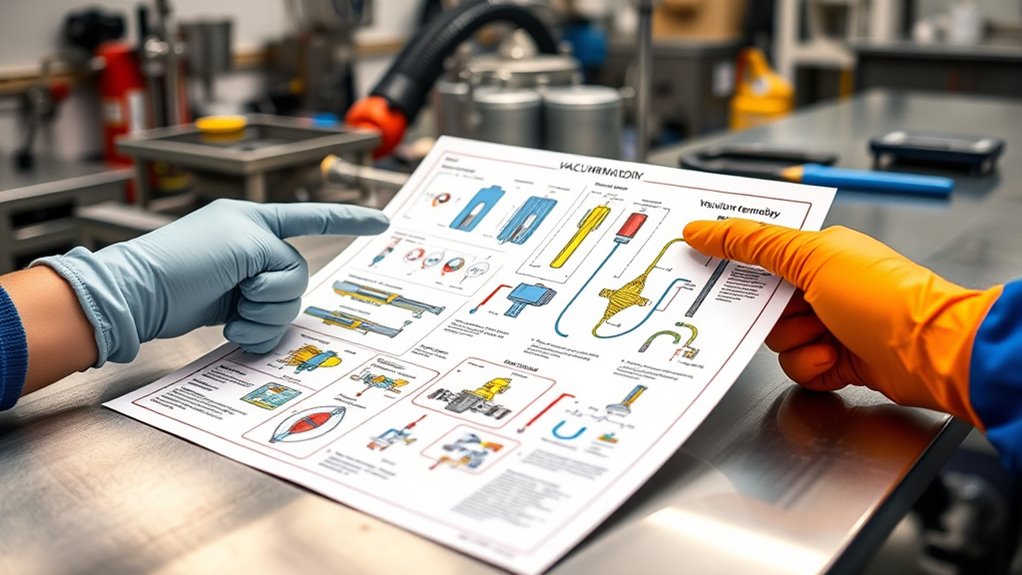

Vacuum Processes and Techniques

Vacuum processes and techniques are vital for controlling environments where air and other gases are removed to achieve specific conditions. When working with a vacuum chamber, you rely on methods like pumping and baking to reach desired pressures. Leak detection is imperative to guarantee the system maintains its vacuum integrity; even tiny leaks can compromise results. Techniques such as using helium sniffers or helium mass spectrometers help identify leaks quickly. You might also perform vacuum baking to outgas materials, improving vacuum quality. Understanding these processes helps prevent contamination and guarantees consistent outcomes. Proper pump selection for different vacuum levels is crucial to ensure efficiency and system longevity. Leak detection methods to identify system weaknesses include various testing tools and procedures. Baking techniques to remove residual gases enhance the vacuum environment further. Maintaining vacuum integrity over time involves regular monitoring and system maintenance. Pressure relief mechanisms are also essential components to prevent potential overpressure situations during vacuum operations.

Common Vacuum Terms and Their Usage

Ever wondered what terms like “pressure” or “ultimate vacuum” really mean in the context of vacuum technology? Understanding these common vacuum terms helps you communicate more effectively. “Pressure” measures how much air or gas is present inside a vacuum system, usually expressed in units like Torr or Pascal. “Ultimate vacuum” refers to the lowest possible pressure achievable, indicating the highest level of vacuum. You’ll also encounter “vacuum sealings,” which are essential for maintaining vacuum integrity and preventing leaks. When issues arise, “leak detection” becomes critical to identify and fix breaches that compromise system performance. Knowing these terms empowers you to troubleshoot, optimize, and maintain vacuum systems with confidence, ensuring your processes run smoothly and efficiently. For example, familiarizing yourself with vacuum pump types can help select the best equipment for specific applications.

Troubleshooting and Maintenance Vocabulary

When troubleshooting vacuum issues, knowing common repair terms helps you identify problems quickly. Routine maintenance phrases guide you through regular checks and part replacements to keep your equipment running smoothly. Mastering this vocabulary makes it easier to communicate with technicians and maintain your vacuum system effectively. Understanding suction power and its impact on cleaning performance can help you diagnose whether a vacuum is functioning properly or needs maintenance.

Common Repair Terms

Have you ever wondered what technicians mean when they talk about “clogged filters” or “lost suction”? These are common repair terms that help pinpoint issues. A vacuum seal problem might cause a loss of pressure, making leak detection essential. When seals weaken or break, your vacuum can’t maintain proper pressure, leading to inefficiency. Troubleshooting may involve checking for:

- Blocked hoses or filters

- Damaged vacuum seals

- Leaks in the system

- Malfunctioning valves

Understanding these terms helps you identify problems quickly. For example, a vacuum seal failure often results in decreased suction, requiring repairs or replacements. Leak detection becomes vital in such cases, ensuring your vacuum system functions efficiently and avoids costly repairs. Proper maintenance practices, such as inspecting vacuum components, can prevent many common issues and extend the lifespan of your system.

Routine Maintenance Phrases

Routine maintenance phrases are essential for understanding and troubleshooting vacuum systems effectively. You’ll often hear terms like “vacuum system calibration,” which guarantees your equipment operates at ideal pressure levels. Regular calibration helps maintain accuracy and performance. Leak detection techniques are also vital; phrases like “pressurize the system,” “listen for hissing sounds,” or “use helium leak detectors” guide you through identifying leaks. These phrases help you quickly diagnose issues, preventing downtime. When performing maintenance, you might say, “Check for leaks,” “Adjust the calibration,” or “Verify the vacuum level.” Mastering these phrases guarantees you can communicate clearly, follow procedures precisely, and keep your vacuum system running smoothly. Using the right terminology minimizes errors and enhances troubleshooting efficiency. Additionally, understanding how to maintain proper pressure levels is crucial for ensuring optimal vacuum performance and avoiding system failures.

Frequently Asked Questions

How Does Humidity Affect Vacuum System Performance?

Humidity affects vacuum system performance by causing moisture condensation inside the system. When humidity levels are high, you might notice increased leaks or contamination, which can reduce efficiency. To prevent this, you need proper humidity control, like using moisture traps or dehumidifiers. Managing humidity helps keep your vacuum system clean, reliable, and working at ideal performance, avoiding potential damage caused by excess moisture.

What Safety Precautions Are Essential for High-Vacuum Operations?

Oh, you’re about to tame the mighty high vacuum beast—how brave! First, prioritize vacuum safety by wearing proper protective gear and avoiding rapid venting. Be aware of high vacuum hazards like implosion risks and toxic leaks. Always check equipment for cracks, ensure proper grounding, and never bypass safety interlocks. Remember, in high-vacuum operations, safety isn’t optional; it’s the only way to prevent turning your lab into a disaster zone.

Can Vacuum Terminology Vary Across Different Industries?

You’ll find that vacuum terminology can differ across industries, impacting how you approach vacuum pump maintenance and leak detection techniques. For example, in semiconductor manufacturing, precise terms are critical, while in medical settings, simpler language prevails. Understanding these variations helps you communicate effectively, avoid misunderstandings, and guarantee proper maintenance procedures, ultimately improving your system’s efficiency and safety across different fields.

How Do Environmental Factors Influence Vacuum Measurement Accuracy?

Environmental factors critically impact vacuum measurement accuracy. You need to pay attention to pressure calibration, ensuring your instruments are correctly calibrated to account for temperature and atmospheric pressure changes. Contamination control also matters, as dust or moisture can skew readings. By managing these factors, you help maintain precise measurements, avoiding errors caused by fluctuating environmental conditions. This proactive approach ensures your vacuum system operates reliably and accurately in varying environments.

What Are Emerging Trends in Vacuum Technology Advancements?

Did you know that the global vacuum technology market is expected to reach $3.8 billion by 2025? You should stay ahead by exploring emerging trends like smarter vacuum pump maintenance and using innovative vacuum materials. These advancements improve efficiency, reduce downtime, and extend equipment lifespan. Embracing these innovations helps you optimize your processes and stay competitive in a rapidly evolving industry.

Conclusion

By mastering these vacuum terms, you’ll navigate the complex world of vacuum technology with confidence. Think of this glossary as your compass—guiding you through intricate concepts, precise measurements, and essential equipment. As you deepen your understanding, you’ll uncover the harmony behind the science and the art of vacuum systems. Embrace this knowledge, and watch how clarity transforms your expertise—turning jargon into a language you command effortlessly.