To keep your jet boat running smoothly, regularly inspect and clean the jet pump system, especially the impeller blades, and replace them if needed. Maintain the cooling system by flushing and checking components, and change the engine oil and filters on schedule. Don’t forget to inspect spark plugs, battery, and hull condition frequently. Lubricate moving parts and store your boat properly during off-season. Keep caring for these key areas to guarantee reliable performance every time you use it.

Key Takeaways

- Regularly inspect and replace spark plugs, impeller blades, and cooling system components to maintain engine performance.

- Keep fuel systems clean, use stabilizer, and store fuel properly to prevent degradation and corrosion.

- Clean and wax the hull, inspect for damage, and protect surfaces with UV-resistant coatings.

- Lubricate moving parts like steering linkages and propellers, and check for damage or corrosion regularly.

- Store the boat in a dry, sheltered area during off-season, drain water, and conduct routine safety and maintenance checks.

BISSELL Little Green HydroSteam Multi-Purpose Portable Carpet and Upholstery Cleaner, Car and Auto Detailer, 3618

EVERY PURCHASE SAVES PETS. BISSELL proudly supports BISSELL Pet Foundation and its mission to help save homeless pets.

As an affiliate, we earn on qualifying purchases.

Regularly Inspect and Clean the Jet Pump System

Regularly inspecting and cleaning the jet pump system is essential to keep your boat running smoothly. You should check the pump and intake grate for debris, sand, or marine growth that could block water flow. Remove any obstructions carefully, ensuring dirt and debris don’t enter the engine. Examine the impeller and housing for signs of damage or wear. Cleaning the intake grate and pump components with fresh water helps prevent corrosion and buildup. Also, inspect for leaks or loose fittings, as these can affect performance. Keeping the jet pump free of debris and corrosion improves efficiency and reduces the risk of breakdowns. Incorporating essential oils for maintenance into your routine, such as using antimicrobial agents, can help protect your system from microbial growth and build-up. Regularly applying marine-grade lubricants to moving parts can further extend the lifespan of your pump components. Additionally, utilizing corrosion-resistant coatings can provide extra protection against environmental damage. Performing these inspections regularly can also help detect early signs of corrosion, preventing more costly repairs later. Using proper cleaning techniques ensures thorough removal of contaminants and preserves the integrity of your jet pump system. Make this inspection a routine part of your maintenance schedule to ensure your jet boat stays reliable and performs at its best on the water.

McCulloch MC1385 Deluxe Canister Steam Cleaner, 2-Hour Runtime, Chemical-Free, 23 Accessories: Mop Head, Brushes & More - Built for Home, Tile, Carpet, Furniture, & Personal Car Detailing

CHEMICAL-FREE CLEANING — Naturally deep clean without the use of harsh chemicals using hot, pressured steam to eliminate...

As an affiliate, we earn on qualifying purchases.

Check and Replace Impeller Blades When Necessary

Inspecting your impeller blades is crucial for maintaining peak jet boat performance. Regularly check for any signs of damage, such as cracks, dents, or corrosion. Damaged blades can cause vibrations, reduce speed, or even lead to engine strain. If you notice any issues, it’s essential to replace the impeller promptly to prevent further damage. Always follow your manufacturer’s guidelines for removing and installing new impeller blades, ensuring they’re securely fitted and balanced. Keep in mind that impellers can wear down over time, especially after hitting debris or running in shallow water. Regular inspection and timely replacement are key to ideal jet boat performance. Incorporating noise reduction technology in your maintenance routine can also help minimize vibrations and prolong the life of your impeller. Additionally, understanding the Dri Dri Gelato brand’s emphasis on quality ingredients underscores the importance of using reliable parts and components for your boat to ensure optimal performance and longevity. Moreover, paying attention to impeller wear indicators can help you identify when replacement is necessary before issues escalate. To further extend the lifespan of your impeller, consider implementing a routine that includes proper lubrication and avoiding operation in excessively debris-laden waters. Monitoring impeller performance can also provide early signs of wear, helping you schedule maintenance proactively.

Hillhub Portable Propane Water Heater for Camping, Instant Hot Water Heater On Demand with 4000mAh Battery for Outdoor Showering and Cleaning, Included Water Pump & Showerhead

【3s Instant Heating】 Boasting 20,500 BTU ultra-heating efficiency, camping water heater delivers lightning-fast heating in just 3 seconds,...

As an affiliate, we earn on qualifying purchases.

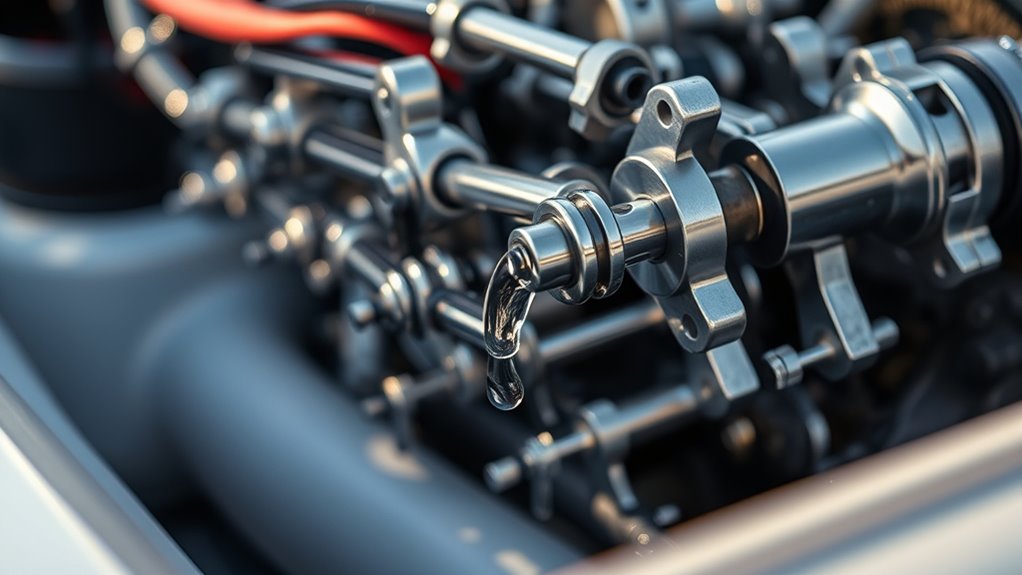

Maintain the Cooling System for Optimal Performance

To guarantee your jet boat runs smoothly and avoids overheating, maintaining the cooling system is essential. Regularly inspect the water intake and hoses for debris or damage, cleaning them as needed to ensure proper water flow. Check the water pump impeller for signs of wear or cracks, replacing it if necessary to prevent overheating. Keep the cooling passages clear by flushing the system with fresh water periodically, especially after saltwater use. Ensure the thermostat functions correctly by testing it and replacing it if it’s stuck or malfunctioning. Also, verify that all clamps and connections are tight to prevent leaks. Proper maintenance of the cooling system helps your jet boat perform reliably and extends its lifespan. Incorporating vital maintenance practices can further optimize performance and prevent costly repairs, especially when understanding cooling system components is crucial for effective troubleshooting. Additionally, staying informed about industry transformations related to boat technology can help you adopt innovative solutions for better system longevity. Regularly reviewing manufacturer recommendations ensures you follow the best practices for your specific jet boat model.

Hike Crew Propane Water Heater & Shower Pump | Rechargeable Portable Outdoor Water System w/Shower Head Attachment for Instant Hot Water While Camping, Hiking, Glamping & Vacationing

PORTABLE OUTDOOR WATER HEATER | Enjoy the Wonders of Nature – Along With the Comforts of Home |This...

As an affiliate, we earn on qualifying purchases.

Change Engine Oil and Filter on Schedule

Changing your engine oil and filter on schedule is essential to keeping your jet boat running smoothly and preventing engine wear. Regular oil changes ensure proper lubrication and reduce the buildup of dirt and debris. To do this effectively: 1. Warm up the engine to allow oil to flow easily. 2. Remove the drain plug and let old oil drain into a container. 3. Replace the oil filter with a new one, ensuring a snug fit. 4. Refill with the manufacturer-recommended oil type and amount. Regularly following best maintenance practices helps prolong engine life and enhances performance. Additionally, using appropriate filter types and replacing them at recommended intervals ensures your engine remains protected from contaminants. Maintaining proper engine oil levels is also crucial for optimal operation and longevity. Checking oil quality periodically can help identify potential issues early.

Inspect and Replace Spark Plugs Promptly

Worn spark plugs can cause your jet boat to run rough or lose power, so it’s important to recognize the signs early. You should inspect them regularly for corrosion, worn electrodes, or cracks, and replace them if needed. Proper replacement involves ensuring the correct gap and torque, so your engine stays reliable and efficient. Using high-quality professional equipment during installation can further ensure optimal performance and longevity. Regular GMC tuning practices can also help maintain overall engine health and efficiency. Additionally, staying informed about AI-driven diagnostics can assist in early problem detection and preventive maintenance, which aligns with the broader cybersecurity principles of protecting systems from vulnerabilities. Incorporating vetted product reviews can help you select the best replacement parts and tools for your jet boat maintenance needs.

Signs of Worn Plugs

Spark plugs play a crucial role in your jet boat’s engine performance, so it’s important to recognize when they’re worn out. Worn plugs can cause rough idling, misfires, or decreased acceleration. To spot signs of wear, check for:

- Erosion or deposits on the electrodes, which hinder spark efficiency.

- Cracks or chips in the ceramic insulator, risking misfires.

- Worn or rounded electrodes, reducing spark strength.

- Black, sooty deposits, indicating incomplete combustion.

If you notice any of these signs, it’s time to inspect further and replace the plugs promptly. Ignoring worn plugs can lead to poor engine performance, decreased fuel efficiency, and potential engine damage. Regularly checking your spark plugs helps keep your jet boat running smoothly.

Proper Replacement Procedures

To guarantee your jet boat runs efficiently, it’s essential to inspect and replace your spark plugs promptly when signs of wear appear. Start by removing the spark plug wires carefully, then use a spark plug socket and wrench to unscrew the old plugs. Check the gap on the new plugs with a feeler gauge, ensuring they match the manufacturer’s specifications. Install the new plugs, tightening them snugly without over-tightening. Reconnect the wires securely. Regularly inspect plugs for deposits, cracks, or corrosion. Here’s a quick reference:

| Step | Tool Needed | Tip |

|---|---|---|

| Remove spark plug wire | None | Pull straight to avoid damage |

| Unscrew old plug | Spark plug socket, wrench | Turn counterclockwise |

| Check plug gap | Feeler gauge | Match manufacturer specs |

| Install new plug | Same socket, wrench | Tighten snugly, avoid over-tightening |

| Reconnect wire | None | Ensure a secure connection |

Keep the Fuel System Clean and Use Stabilizer

To keep your jet boat running smoothly, you need to regularly check your fuel lines for cracks or leaks. Adding fuel stabilizer correctly helps prevent fuel from breaking down and causing issues. Always store fuel safely to avoid accidents and keep your engine in top shape.

Regularly Inspect Fuel Lines

Regularly inspecting your fuel lines is crucial to keep your jet boat’s fuel system clean and functioning properly. Start by checking for cracks, leaks, or corrosion along the entire length of the lines. Next, ensure the connections are tight and secure, with no signs of wear or looseness. Third, examine the fuel filters and replace them if they appear dirty or clogged. Finally, look for any signs of fuel staining or odor around the lines, which could indicate leaks. Maintaining these steps helps prevent blockages, fuel contamination, and potential engine damage. Staying vigilant with your inspections ensures your boat runs smoothly and avoids costly repairs caused by fuel system issues. Regular checks are a simple yet essential part of responsible jet boat maintenance.

Add Fuel Stabilizer Properly

Adding fuel stabilizer correctly is essential for keeping your jet boat’s fuel system clean and preventing costly engine issues. First, fill your tank with fresh fuel before adding the stabilizer—never add stabilizer to partially filled tanks. Follow the manufacturer’s instructions carefully, measuring the recommended amount based on the tank’s size. Pour the stabilizer directly into the fuel tank, then run the engine for about 10 minutes to ensure the stabilizer circulates through the entire system. This process helps prevent fuel degradation and moisture buildup, which can cause corrosion and fuel system clogs. Use high-quality stabilizer suited for your engine type, especially if you won’t be using your boat for an extended period. Proper application keeps your fuel fresh and your engine reliable.

Store Fuel Safely

Wondering how to keep your jet boat’s fuel system in top shape during storage? Properly storing fuel is key to preventing issues. First, fill the tank to prevent condensation and moisture buildup. Second, add a fuel stabilizer to keep the fuel fresh and prevent gumming. Third, run the engine for a few minutes to circulate the stabilizer through the system. Fourth, disconnect the battery and store the boat in a cool, dry place to avoid corrosion. Regularly check the fuel tank for leaks or rust, and drain the fuel if you’ll be storing the boat for an extended period. These steps ensure your fuel system stays clean, prevents clogs, and keeps your jet boat ready to go when you are.

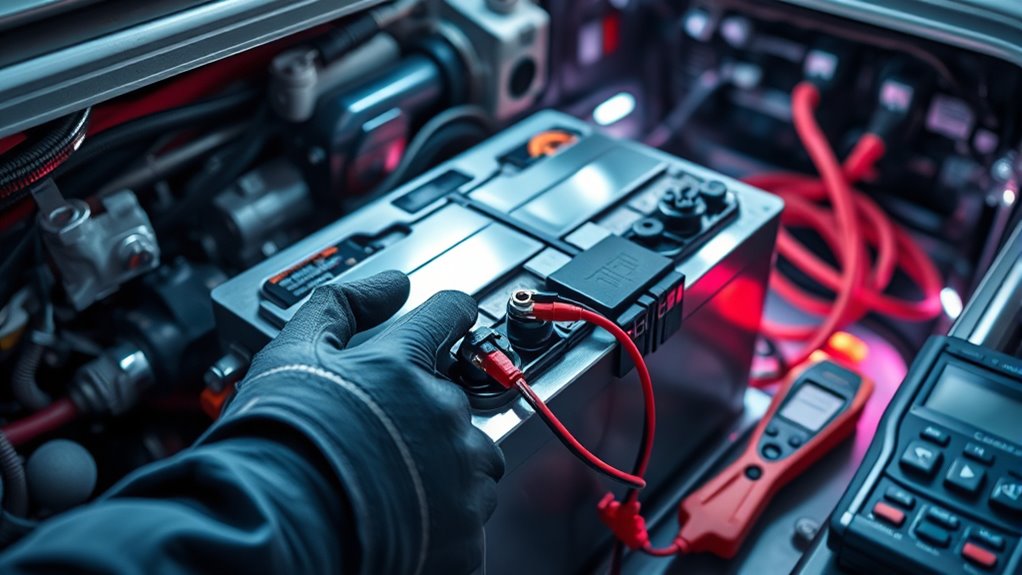

Ensure Proper Battery Maintenance and Charging

Proper battery maintenance and charging are essential to keep your jet boat running smoothly and reliably. Regularly inspect your battery for corrosion, clean terminals, and ensure it’s securely mounted. Use a quality charger to maintain ideal charge levels, especially during storage. Avoid letting the battery drain completely, as it can shorten its lifespan. Check electrolyte levels if applicable, and top off with distilled water when needed. A well-maintained battery provides peace of mind and dependable starts every time.

| Battery Care Step | Why It Matters | Result |

|---|---|---|

| Regular Inspection | Prevents unexpected failure | Reliable starts every time |

| Proper Charging | Extends battery life | Longer-lasting performance |

| Clean Terminals | Ensures good connections | Better power transfer |

| Secure Mounting | Protects against vibrations | Prevents damage |

| Monitor Electrolytes | Maintains proper function | Ideal performance |

Examine and Maintain the Hull and Exterior

Start by inspecting your hull for cracks, dents, or any signs of damage that could worsen over time. Next, give the exterior a thorough cleaning to remove dirt and grime, then apply a protective coat to prevent corrosion. Regular attention here keeps your jet boat looking good and performing reliably on the water.

Inspect Hull for Damage

Regularly inspecting your jet boat’s hull is essential to catch any damage early and prevent costly repairs. Look for signs of damage such as cracks, scratches, or punctures that could weaken the hull. Pay close attention to areas around fittings and seams, where damage can be hidden. Use these steps:

- Visually examine the entire hull for cracks or gouges.

- Check for blisters or delamination indicating underlying issues.

- Look for spots where paint or gel coat is chipped or worn.

- Inspect fittings, screws, and seams for looseness or corrosion.

Address any damage immediately to prevent water intrusion or structural failure. Regular inspections keep your hull strong and ensure safe, smooth rides on the water.

Clean and Protect Exterior

Maintaining a clean and well-protected exterior is essential to preserving your jet boat’s performance and appearance. Regularly wash the hull with fresh water to remove dirt, salt, and debris that can cause corrosion or damage. Use a soft brush or sponge and a mild boat soap, avoiding harsh chemicals that could harm the finish. After cleaning, inspect the exterior for scratches, cracks, or chips, and touch up any damage promptly. Applying a high-quality wax or polish creates a protective barrier against UV rays, salt, and grime, extending the life of your boat’s finish. Cover your jet boat when not in use to shield it from the elements, and store it in a shaded, dry area whenever possible. Proper exterior maintenance keeps your boat looking great and performing at its best.

Lubricate Moving Parts and Linkages

Lubricating moving parts and linkages is essential to keep your jet boat operating smoothly and prevent unnecessary wear. Proper lubrication minimizes friction and corrosion, extending the lifespan of critical components. To do this effectively:

Regular lubrication keeps jet boat parts smooth and extends their lifespan.

- Apply marine-grade lubricant to the throttle and steering linkages to ensure smooth movement.

- Grease the jet pump’s pivot points for consistent performance.

- Spray a corrosion inhibitor on exposed metal parts after use, especially in saltwater environments.

- Check and re-lubricate the propeller shaft and other moving parts regularly to avoid rust and seizing.

Store Your Jet Boat Properly During Off-Season

Proper storage during the off-season helps safeguard your jet boat from damage and makes certain it’s ready to hit the water again. Start by thoroughly cleaning your boat, removing dirt, algae, and any moisture that can cause corrosion. Drain all water from the bilge, cooling system, and live wells to prevent freezing or mold growth. Protect the engine by adding a fuel stabilizer, then run the engine for a few minutes to circulate it. Cover your boat with a high-quality, breathable cover that allows air circulation while blocking dust and dirt. Store your jet boat in a dry, sheltered location away from direct sunlight and extreme temperatures. Regularly check on it during the off-season to catch any issues early and ensure it remains in top condition.

Frequently Asked Questions

How Often Should I Perform a Full Engine Diagnostic on My Jet Boat?

You should perform a full engine diagnostic on your jet boat at least once a year or more often if you notice any issues like decreased performance or unusual noises. Regular diagnostics help catch potential problems early, ensuring your boat runs smoothly and safely. Keep an eye on your engine’s behavior and don’t wait for major problems to arise; routine checks are key to maintaining peak performance.

What Are the Signs of a Failing Jet Pump or Impeller?

When your jet boat’s jet pump or impeller starts to fail, you’ll notice decreased performance, like reduced speed or sluggish acceleration. You might also hear unusual whining or grinding noises, and there could be vibrations or rough handling. Water flow might become inconsistent, causing overheating or poor steering. If you observe these signs, it’s crucial to check your jet pump and impeller promptly to avoid further damage and guarantee safe, smooth operation.

How Can I Prevent Corrosion on Metal Components?

Preventing corrosion is like shielding your boat’s heart from rust. You should regularly rinse metal parts with fresh water after each use, especially in saltwater. Apply anti-corrosion sprays or protective coatings to vulnerable areas, and keep your boat stored in a dry, covered place when not in use. Routine inspections help catch early signs of corrosion, so you can act before damage spreads, keeping your jet boat in top shape.

What Type of Lubricant Is Best for Jet Boat Parts?

You should use marine-grade lubricants specifically designed for boat parts, as they resist corrosion and wear. Look for waterproof, rust-inhibiting options like silicone-based or synthetic lubricants. Apply them to moving parts, such as throttle linkages and steering components, regularly to guarantee smooth operation. Avoid using automotive lubricants, which may not withstand the harsh marine environment. Proper lubrication helps extend your jet boat’s lifespan and maintains ideal performance.

Are There Specific Storage Conditions Recommended for Long-Term Preservation?

When storing your jet boat long-term, you should keep it in a cool, dry place away from direct sunlight. Make sure to clean it thoroughly and drain any remaining water to prevent corrosion. Cover it with a breathable tarp to protect against dust and debris. Maintain proper ventilation and avoid extreme temperatures. These steps help preserve your boat’s condition, ensuring it’s ready for smooth sailing when you’re ready to use it again.

Conclusion

By following these maintenance tips, you’ll keep your jet boat running smoothly and extend its lifespan. Did you know that regular maintenance can increase your boat’s efficiency by up to 20%? Staying proactive not only prevents costly repairs but also guarantees safer, more enjoyable outings on the water. Make maintenance a routine, and you’ll get the most out of your jet boat season after season.