Inside the next-gen digital inverter motor revolution, you’ll see significant improvements driven by smarter control algorithms, advanced materials, and innovative designs. These motors are more efficient, durable, and energy-saving, transforming industries like transportation and electronics. They incorporate precise control, better thermal management, and eco-friendly features that reduce waste and emissions. To discover how these breakthroughs are shaping the future of technology, explore further to uncover the full scope of these exciting advancements.

Key Takeaways

- Next-gen digital inverter motors leverage advanced control algorithms for enhanced energy efficiency, precise performance, and noise reduction.

- Innovations in magnetic materials and compact design enable more powerful, durable motors integrated seamlessly into modern devices.

- Manufacturing automation and material science advancements improve motor production speed, reliability, and resistance to harsh environments.

- These motors support sustainable energy solutions through reduced power consumption, recycling initiatives, and eco-friendly component materials.

- Future developments focus on integrating smart grid capabilities, wireless charging, and meeting evolving safety and environmental standards.

Oxseryn Power Equipment 4400 Watts Inverter Generator Gas Powered, Portable Open Frame Generator, Low Noise with ECO Mode, RV Ready, Emergency Home Backup

𝗣𝗼𝘄𝗲𝗿𝗳𝘂𝗹 𝗢𝘂𝘁𝗽𝘂𝘁 - 4400 peak watts and 3400 running watts, perfect for RV camping and home backup

As an affiliate, we earn on qualifying purchases.

The Evolution of Electric Motor Technology

Electric motor technology has come a long way, transforming how we power everything from household appliances to electric vehicles. You’ve likely noticed improvements driven by battery innovations, which now provide higher energy density and longer life, fueling more efficient motors. Manufacturing automation has also played a crucial role, enabling faster, more precise production processes that reduce costs and improve quality. These advancements have allowed manufacturers to develop compact, powerful motors that integrate seamlessly into modern devices. As a result, electric motors are more efficient, reliable, and adaptable than ever before. The evolution of motor design techniques has further optimized performance and energy savings, making electric motors more accessible and sustainable for everyday use.

Varpoolfaye Variable Speed Pool Pump,1.8HP, 220V-240V, Inground Pool Pump, High Flow 9114 GPH Energy-Efficient Self Priming Above Ground Swimming Pool Pumps with Filter Basket

1.8hp Pool Pump: With 1.8hp powerful permanent magnet motor, operating on 220-240V/60Hz, it is stable, provides high performance...

As an affiliate, we earn on qualifying purchases.

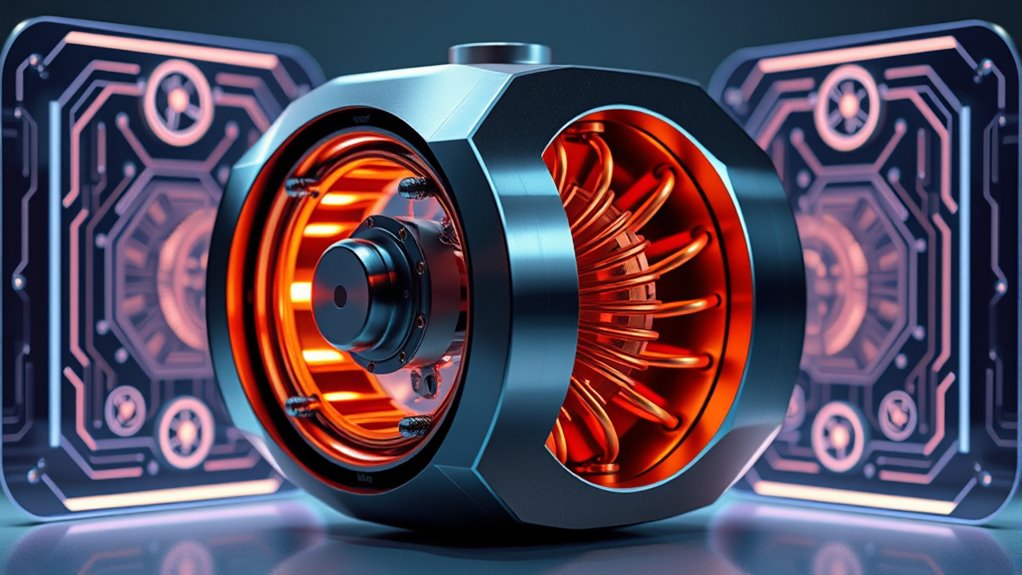

Key Components of Digital Inverter Motors

Digital inverter motors rely on several key components that work together to optimize performance and efficiency. The rotor design is vital, influencing how smoothly the motor runs and how effectively it converts electrical energy into mechanical power. Magnetic materials, such as neodymium or ferrite, are used to enhance magnetic fields, increasing torque and reducing energy loss. The inverter electronics control the power flow, adjusting speed and torque precisely. Additionally, understanding regional legal resources can be beneficial when navigating technical regulations and standards for manufacturing and safety compliance.

Here’s a quick overview:

| Component | Function | Key Feature |

|---|---|---|

| Rotor Design | Converts electrical to mechanical energy | Optimized for minimal losses |

| Magnetic Materials | Strengthen magnetic fields | High-performance alloys |

| Power Electronics | Regulate electrical input | Precise control of motor speed |

| Cooling System | Prevents overheating | Maintains efficiency |

Aquastrong Variable Speed Pool Pump In/Above Pool Pump Energy Efficient High Flow Powerful Self Primming Swimming Pool Pumps with Filter Basket,Black

Powerful Performance: Our smart variable speed pool pump allows you to customize speeds from 1200 RPM(3566GPH) to 4000...

As an affiliate, we earn on qualifying purchases.

Advanced Control Algorithms and Their Impact

Advanced control algorithms enable your digital inverter motor to achieve precise motor control, optimizing performance in real time. This leads to significant energy efficiency gains and reduces overall power consumption. Additionally, smoother operation minimizes mechanical stress, extending the motor’s lifespan and reliability. Incorporating advanced safety features helps protect the motor from overloads and potential damage, ensuring consistent performance over time.

Precision Motor Control

When it comes to achieving peak performance in next-generation inverter motors, precision motor control plays a critical role. It guarantees the motor operates smoothly through meticulous motor calibration, which fine-tunes the system for optimal responsiveness. Advanced control algorithms enable real-time adjustments, reducing vibrations and mechanical stress. This leads to significant noise reduction, creating quieter operation and enhancing user comfort. Precise control also improves torque accuracy and stability, even under variable loads, boosting overall efficiency. By continuously monitoring motor behavior, these algorithms adapt quickly, minimizing errors and preventing misalignments. Additionally, understanding the importance of control methodologies helps in developing more robust and adaptive systems. Together, motor calibration and noise reduction elevate the motor’s performance, guaranteeing it runs at peak efficiency while maintaining longevity and reliability. This level of control is essential for revealing the full potential of next-generation inverter motors.

Energy Efficiency Gains

By implementing sophisticated control algorithms, next-generation inverter motors considerably improve energy efficiency. These algorithms optimize motor operation by precisely adjusting power delivery, reducing wasted energy. Better integration with advanced battery technology ensures that power use is maximized, extending battery life and range. As a result, your user experience becomes smoother, with more reliable performance and less frequent charging. Enhanced control allows the motor to operate at peak efficiency across various conditions, minimizing energy loss. This integration of advanced control strategies not only benefits the environment by lowering overall energy consumption but also reduces your operating costs. You’ll notice improved responsiveness and longer-lasting battery life, making your vehicle or appliance more reliable and cost-effective over time. These gains mark a significant step forward in digital inverter motor technology.

Reduced Mechanical Stress

Enhanced control algorithms not only boost energy efficiency but also considerably reduce mechanical stress on motor components. By precisely managing current and voltage, these algorithms minimize sudden torque changes that cause wear. This leads to less strain on bearings and shafts, extending motor lifespan. Improved lubrication techniques further decrease friction, reducing heat and mechanical fatigue. Noise reduction methods, integrated with advanced control, dampen vibrations caused by motor operation, lessening mechanical impact. Together, these innovations ensure smoother, quieter operation, lowering the risk of component failure. Additionally, implementing vibration damping techniques can further mitigate mechanical stresses. As a result, your motor experiences less mechanical stress, which enhances durability and reliability. Embracing these control strategies not only optimizes performance but also protects your investment by maintaining the motor’s integrity over time.

Varpoolfaye 1.8 HP Variable Speed Pool Pumps, Self-Primming Above/Inground Pool Pump 9114 GPH with Timer 220-240V

【CUT ENERGY COSTS by UP TO 80%】This Smart Variable-Speed Pool Pump automatically learns your pool’s needs, adjusting its...

As an affiliate, we earn on qualifying purchases.

Energy Efficiency and Sustainability Benefits

You’ll notice that next-gen digital inverter motors use less power, making your energy bills lower. They operate more eco-friendly by reducing emissions and waste. This means you can enjoy better performance while supporting sustainability efforts.

Reduced Power Consumption

The next-generation digital inverter motor considerably reduces power consumption, making your appliances more energy-efficient and environmentally friendly. This innovation optimizes energy use through advanced control, leading to lower electricity bills and a smaller carbon footprint. Key benefits include:

- Improved battery technology that enhances energy storage and efficiency.

- Smarter user interface options that allow you to customize power settings for maximum savings.

- Precise motor control reduces unnecessary energy waste during operation.

- Enhanced overall system efficiency, ensuring less energy is needed for the same performance.

- Incorporating skincare innovation principles from trusted brands like Patchology can further support sustainable and eco-conscious product choices.

Eco-Friendly Operation

By adopting the next-gen digital inverter motor, your appliances operate more sustainably, substantially reducing their environmental impact. These motors enhance energy efficiency, helping you cut down on power usage and lower carbon emissions. As consumer awareness of eco-friendly practices grows, these appliances align with recycling initiatives that promote responsible disposal and reuse of components. The advanced design minimizes waste and encourages manufacturers to develop more sustainable products. Your choices support a greener future by reducing resource consumption and waste. Additionally, the increased efficiency often extends appliance lifespan, decreasing the need for replacements. This holistic approach to eco-friendly operation benefits the environment while offering you cost savings. Embracing these innovations makes it easier to contribute to sustainability efforts, reflecting your commitment to environmental responsibility.

Innovations in Material Science and Durability

Advancements in material science are transforming the durability and performance of next-generation digital inverter motors. You’ll benefit from innovations like nanomaterial enhancements, which strengthen motor components at the molecular level, increasing resilience and efficiency. Additionally, composite durability ensures the motor can withstand extreme conditions without degrading. Here are some key developments:

- Nanomaterial enhancements improve thermal management and wear resistance.

- Composite materials reduce weight while maintaining strength.

- Advanced coatings prevent corrosion and extend lifespan.

- High-strength alloys increase resistance to mechanical stress.

- The integration of corrosion resistance properties further enhances the longevity of these motors in harsh environments.

These innovations allow your motor to operate longer, more reliably, and with ideal performance, pushing the boundaries of current technology.

Applications Transforming Industries

Innovations in material science have opened new possibilities for digital inverter motors, enabling them to revolutionize various industries. One key area is the smart grid, where these motors improve energy efficiency and grid stability by allowing intelligent power management. They facilitate rapid response times and better load control, making energy distribution more reliable and sustainable. Additionally, digital inverter motors are transforming wireless charging technologies, especially in electric vehicles and portable devices. Their high efficiency and precise control enable seamless, fast, and contactless energy transfer, reducing charging times and increasing convenience. Advances in passive voice detection further enhance the development of these motors by improving clarity and technical accuracy in documentation. As a result, industries like transportation, renewable energy, and consumer electronics benefit from these advancements. You’ll see these motors becoming essential components, driving smarter, more connected, and energy-efficient solutions across multiple sectors.

Future Trends and Challenges in Digital Inverter Motors

As digital inverter motors become more widespread, they face both exciting opportunities and significant challenges. You’ll see advancements driven by battery innovations, which boost efficiency and range. However, regulatory changes pose hurdles, requiring compliance with evolving standards. Here are the key trends and challenges:

- Battery innovations will continue to improve energy density and lifespan, supporting more powerful and durable motors.

- Regulatory changes demand stricter safety, efficiency, and environmental standards, potentially increasing development costs.

- Integration with smart systems presents opportunities for enhanced control but requires overcoming cybersecurity concerns.

- Supply chain disruptions could hinder the availability of critical components, delaying adoption.

- The need for robust safety measures to address vulnerabilities and ensure trustworthy operation is increasingly important in the development of digital inverter motors.

Staying ahead means adapting to these trends while addressing hurdles to access the full potential of digital inverter motors.

Frequently Asked Questions

How Do Digital Inverter Motors Compare Cost-Wise to Traditional Motors?

When comparing digital inverter motors to traditional motors, your cost comparison shows that inverter motors often have a higher initial price. However, an affordability analysis reveals they save you money over time through better energy efficiency and reduced maintenance costs. While the upfront investment might seem steeper, the long-term savings make digital inverter motors a smarter, more cost-effective choice for ongoing energy and upkeep expenses.

What Are the Safety Concerns Associated With Advanced Inverter Motor Technology?

When considering advanced inverter motor technology, you should be aware of safety concerns like electrical shock and fire hazards. These motors operate at high voltages, so improper handling or faulty wiring can increase risks. To stay safe, guarantee proper installation, regular maintenance, and use of certified components. Being cautious helps prevent electrical shocks and reduces the chance of fire, making your experience with inverter motors safer and more reliable.

Can Digital Inverter Motors Operate Effectively in Extreme Environmental Conditions?

You might wonder if digital inverter motors can handle extreme environments. They’re designed with environmental durability and corrosion resistance in mind, so they can operate effectively under harsh conditions like high humidity, extreme temperatures, or exposure to corrosive elements. Advanced materials and protective coatings guarantee these motors maintain performance and longevity, making them reliable even in challenging environments. This resilience makes digital inverter motors suitable for diverse applications worldwide.

How Do Digital Inverter Motors Influence Overall System Maintenance Requirements?

You’re hitting the nail on the head—digital inverter motors can reduce your system’s maintenance needs. They often feature advanced sensors that enable predictive maintenance, catching issues early before they become costly problems. Plus, their design minimizes lubrication requirements, saving you time and effort. Overall, these motors help keep your systems running smoothly, lowering downtime and maintenance costs, so you can focus on what really matters.

Are Digital Inverter Motors Compatible With Existing Electrical Infrastructure?

You’ll find that digital inverter motors are generally compatible with your existing electrical infrastructure, but it’s essential to check power grid compatibility first. These motors often require minimal installation complexity, making integration smoother. However, you might need some upgrades or adjustments to your power supply to guarantee peak performance. Always consult a professional to assess your setup, so you can confidently upgrade without risking compatibility issues or unnecessary modifications.

Conclusion

As you embrace the digital inverter motor revolution, you’ll experience enhanced efficiency, improved durability, and innovative applications. You’ll leverage advanced control algorithms, benefit from sustainable energy solutions, and stay ahead of future trends. With ongoing innovations in materials and technology, you’ll transform industries, drive progress, and shape a smarter, greener world. Embrace the change, harness the potential, and lead the way into this exciting next-generation motor era.